Fine Beautiful Tips About How To Check Main Bearing Clearance

Henry de los santos writer.

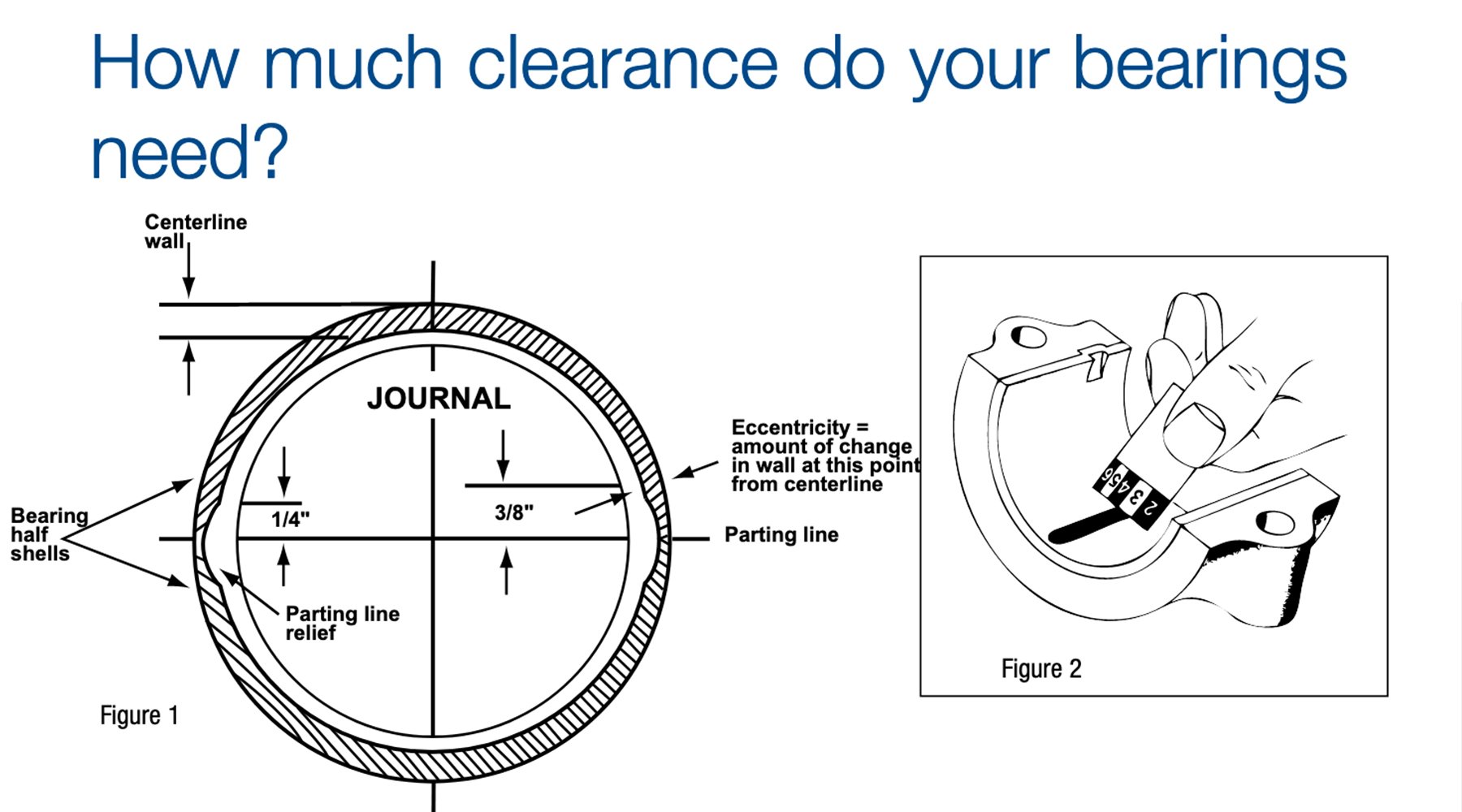

How to check main bearing clearance. Of bearing clearance for every inch of shaft diameter in a stock engine. You first need to set up the bore gauge using a micrometer to. What should main bearing clearance be?

At the heart of your powerplant is the crankshaft, and this baby not only has to. There are no quick and easy ways to establish this critical. Setting bearing clearance for a performance engine is a fundamental step in the building process.

By now, you will have the specs on the crankshaft mains and rods, the journals for both, and the specs on the bearings. Easy to do by the back yard mechanic. Next, it is time to measure the inside diameter of the main bearings.

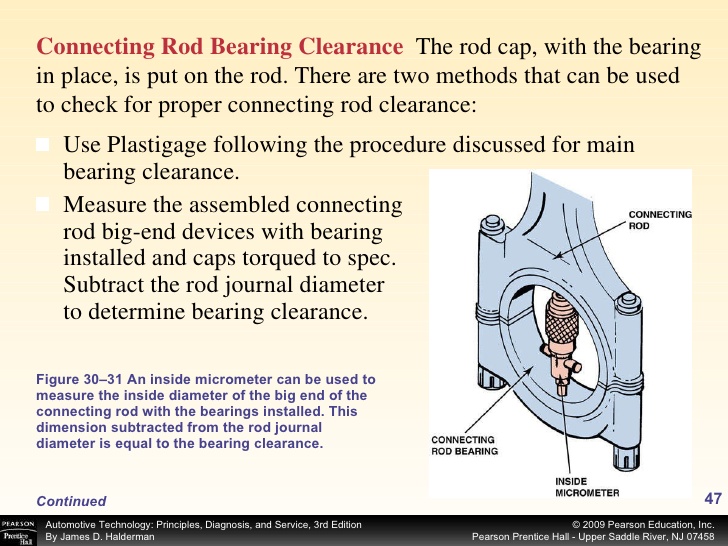

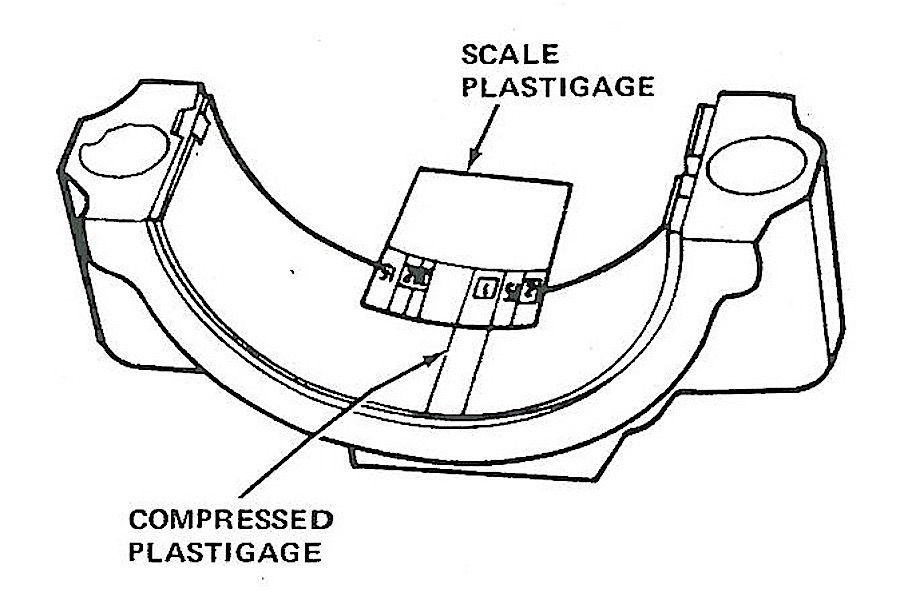

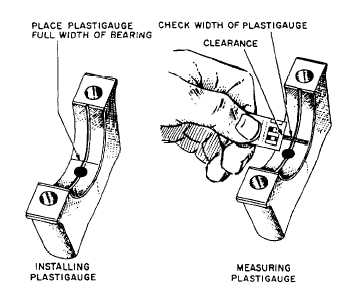

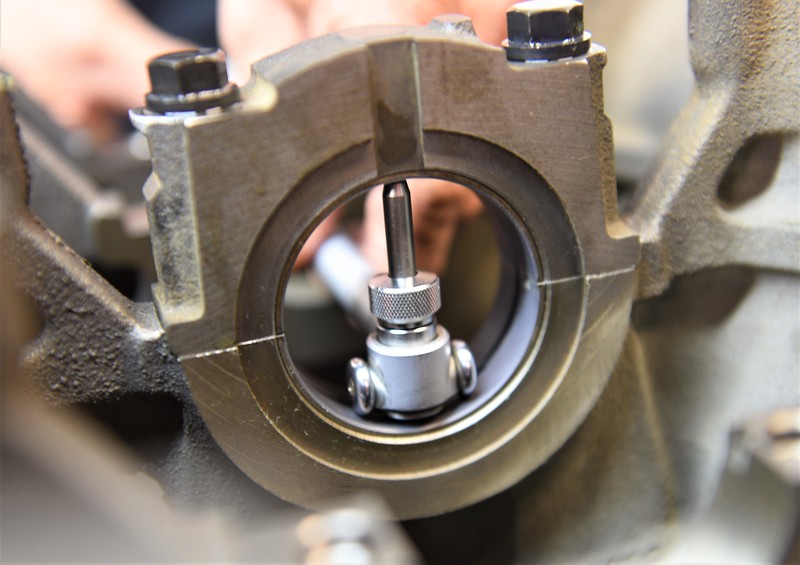

Telescopic feeler gauge / swedish feeler gauge; For the bearing seat with larger diameter, the radial clearance of bearing is larger, so that it can be directly. This is how to check your bearing clearance with a very inexpensive product called plastigauge.

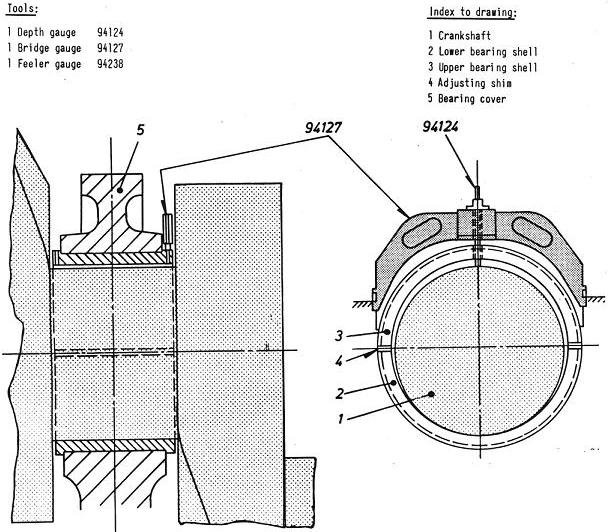

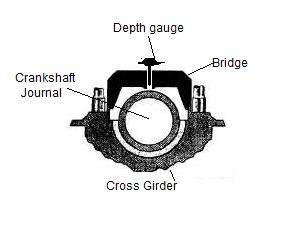

The following are some of the most common methods used onboard ships to measure main bearing clearance: Check radial clearance of bearing. The old rule of thumb is to provide.0007?

Set up a bore gauge to this. This video demonstrates the proper use of plastiguage for determining main bearing clearance. The bearing inside iameter when the bearings are installed at the specified torque without the shaft in place.

If all is right, the crank will spin very freely. If it binds or has tight. As a final check, lubricate the bearings and the crank, put the crank in the block, torque down the caps and spin the crank.

Measurements should be taken at front, center, and rear of each bearing. Using an outside micrometer, carefully measure the crankshaft’s main journal diameters and record the measurements. Subtract the crank spec from the journal spec, and then.

Checking and setting main and rods bearing clearance in car